As industrial manufacturing enters a new era of digitalization and intelligence, additive manufacturing (also known as 3D printing) is injecting innovative vitality into traditional equipment. Heat exchangers, key components in industrial cooling and energy management, have long been constrained by traditional manufacturing processes in terms of design and performance. However, the advent of additive manufacturing has broken this bottleneck, bringing significant breakthroughs in structure and function.

Traditional Constraints of Heat Exchanger Design

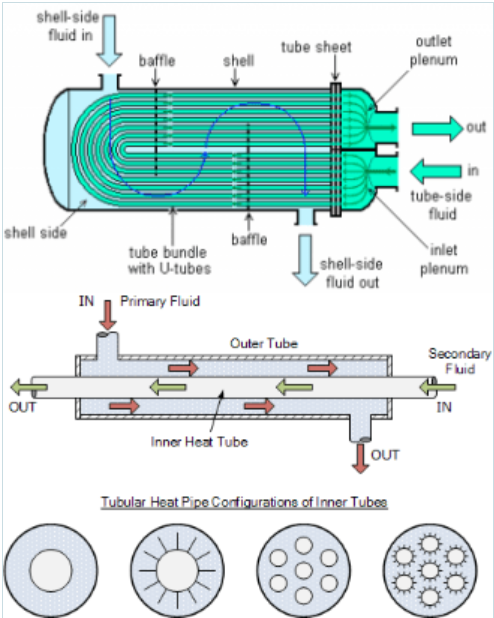

For nearly 30 years, the mechanical design of heat exchangers has seen few disruptive changes. Limited by processes like casting and welding, many complex geometries are difficult to achieve, limiting performance improvements. Optimizing complex three-dimensional channels and flow paths is challenging with traditional manufacturing, making it difficult to achieve a balanced balance of thermal efficiency, power consumption, and size.

The Infinite Possibilities of Additive Manufacturing

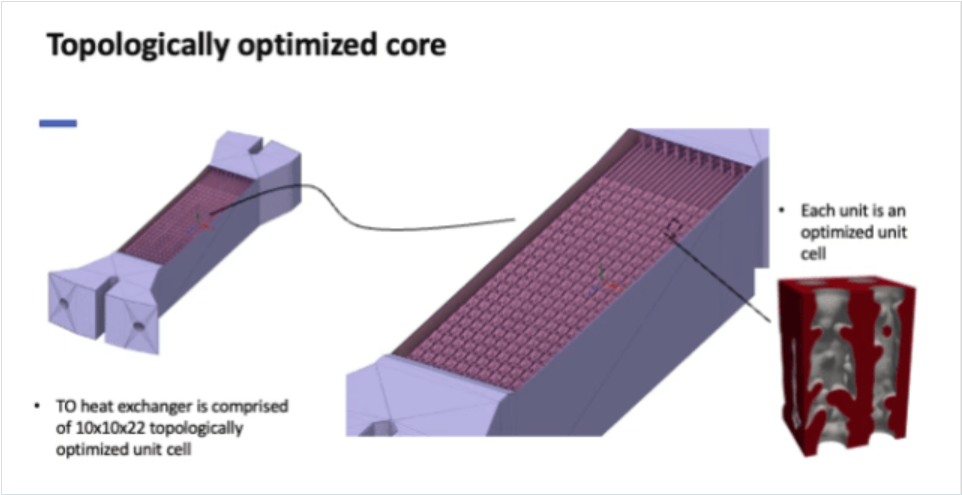

Additive manufacturing technology deposits materials layer by layer, creating complex three-dimensional structures that are difficult to fabricate using conventional processes. Using this technology, the research team designed a heat exchanger with innovative flow channels, cleverly combining high-flow channels with micro-heat transfer channels to precisely control fluid paths and heat transfer efficiency.

This not only improves heat transfer efficiency, achieving a 30% to 50% performance improvement compared to traditional designs, but also significantly reduces the weight and volume of the equipment, making the heat exchanger more suitable for applications such as automotive and aviation, where lightweighting and compactness are paramount.

Technological Breakthrough and Application Prospects

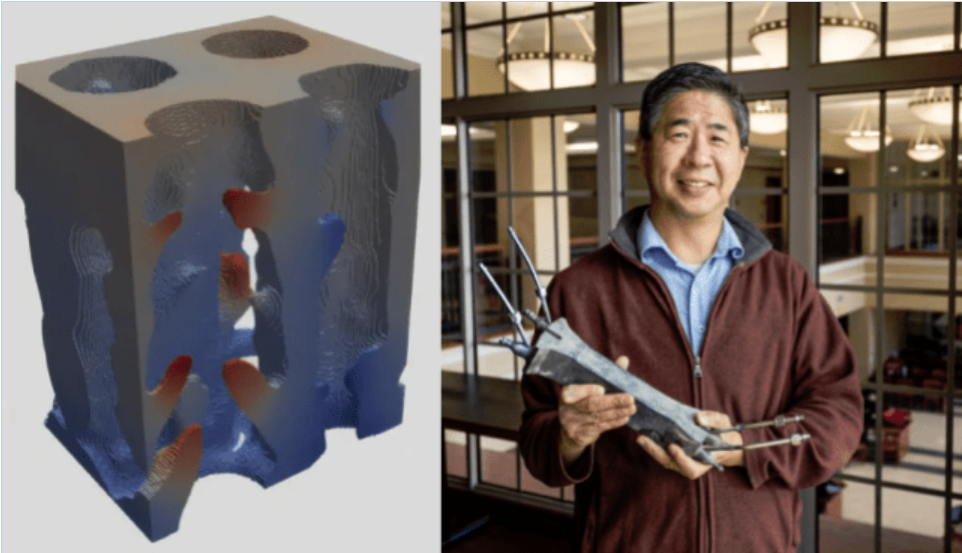

In a collaborative project with the US Navy, the team successfully fabricated a two-phase flow heat exchanger that achieves efficient condensation heat transfer from vapor to liquid. Using virtual simulation technology, they optimized thousands of design options, quickly identifying the optimal structure and significantly shortening the R&D cycle.

In the future, as additive manufacturing materials and processes continue to improve, these high-performance heat exchangers will be widely used in new energy, aerospace, high-performance computing, and other fields, driving these industries towards a new era of greater energy conservation and environmental protection.

Additive manufacturing not only revolutionizes heat exchanger manufacturing but also opens the door to design freedom. Complex fluid structures, previously unattainable through traditional manufacturing, have become a reality at the intersection of digital and physical processes, bringing unprecedented performance leaps to industrial equipment. This is a clear sign of manufacturing’s progress toward intelligent and efficient manufacturing, and a key direction for future industrial innovation.

Leave a Reply